Our Product

We, at  India, are pioneers in the production of superior AAC Blocks or Autoclaved Aerated Concrete Blocks, which are made of a blended proportion of Fly ash, Cement, Lime, Gypsum, Aluminium powder and water. These blocks are our premium products and we are known for these AAC blocks. Though we have a stipulated dimension for our products, we also confirm to our clients' needs.

India, are pioneers in the production of superior AAC Blocks or Autoclaved Aerated Concrete Blocks, which are made of a blended proportion of Fly ash, Cement, Lime, Gypsum, Aluminium powder and water. These blocks are our premium products and we are known for these AAC blocks. Though we have a stipulated dimension for our products, we also confirm to our clients' needs.

Whether you're an architect, engineer, developer or builder, It's worth taking all the time you need in getting to know more than AAC products. AAC block has been in use in Australia, Europe, USA, UK and in many other nations for more than 50 Years at least. The AAC Blocks made by us at Aercon India are manufactured by combining Fly ash, Cement, Lime, Gypsum, Aluminium Powder & Water. AAC Block further cured in Autoclave under the high steam to give its desired strength.

India have come up with these new age building blocks, which perform better than the burnt clay bricks, which are being used extensively worldwide for ages now. However, there are several advantages of using Autoclaved Aerated Concrete blocks over bricks. Let us see how and where our blocks can benefit you.

India have come up with these new age building blocks, which perform better than the burnt clay bricks, which are being used extensively worldwide for ages now. However, there are several advantages of using Autoclaved Aerated Concrete blocks over bricks. Let us see how and where our blocks can benefit you.

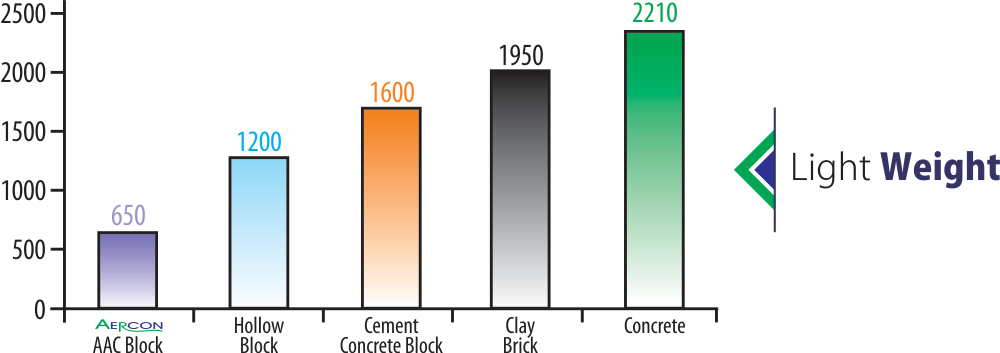

We, at  India, work towards manufacturing the latest building blocks for modern day edifices - Autoclaved Aerated Concrete Blocks, popularly known as AAC Blocks. In India, this is relatively a novel concept as compared to the rest of the world. In terms of usage of the AAC Blocks, we can say that our blocks are increasingly being used for constructing buildings in the most environmental-friendly manner. Yet, these blocks are very light in weight, high strength & cost effective.

India, work towards manufacturing the latest building blocks for modern day edifices - Autoclaved Aerated Concrete Blocks, popularly known as AAC Blocks. In India, this is relatively a novel concept as compared to the rest of the world. In terms of usage of the AAC Blocks, we can say that our blocks are increasingly being used for constructing buildings in the most environmental-friendly manner. Yet, these blocks are very light in weight, high strength & cost effective.

AAC is the material of choice for all building applications including homes, Commercial, Industrial, Schools, Warehouses, Hotels, Hospitals, Retail, Offices, High-rises.....

| Parameter | Aercon AAC Block | Clay Brick |

|---|---|---|

| Size | 625x240x75 to 250mm 600x200x75 to 250mm | or as per customer's requirement |

230x75x115mm |

| Precision in size | 1.5mm( + ) | 5mm( + ) |

| Compressive strength | 3.0 to 4.0 N/mm2(IS 2185, Part-3) | 2.5 to 3.0 N/mm2 |

| Dry density | 550-650 kg/m3(oven dry) | 1950 kg/m3 |

| Fire resistance | 2 to 6 hour (Depending on thickness) | 2 Hour |

| Sound reducing index | 45db for 200mm thick wall | 50db for 230mm thick wall |

| Mortar consumption per M3 with 1:6 | 0.5 bag of cement | 1.40 bag of cement |

| Thermal conductivity | 0.16 W/mk | 0.81 W/mk |

| Maintenance | Less due to its superior properties | Comparatively higher |

| Energy saving | Approx 25% reduction in air conditioner load | No such saving |

| Construction speed | Very high due to bigger size, light weight | Comparatively lower |

| Quality | Uniform and finished | Normally varies |

- Easier to install

- AAC various size option available

- Saving in steel reinforcement

- Saving in mortar

- Saving in plaster

- Reduction in wastage

- Long lasting

- Reduction in HVAC load

- Saving in power infrastructure

- Saving in labour

- Saving in time